I have a dilemma. How should I implement the H bridge?

Each has their own advantages and disadvantages. One choice is the use of the MOSFET over the BJT. I have chosen the MOSFET because it has zero current going through its gate, while the BJT current can be significant, contributing to complications.

I want a small voltage across the device when it has maximum current. In this region of operation, the BJT causes charge to build up. This charge takes time to dissipate. The MOSFET is much faster in this region of operation. Also, the minimum voltage for the BJT is much higher, and is independent of the base voltage. The minimum voltage for the MOSFET for a given current is much lower, and it does depend on the gate to source voltage. The equation for the MOSFET is much simpler to implement, and is readily adapted to many specifications. The transport model for the BJT has many more variables and equations, that could be beneficial when looking for a solution.

One final consideration is whether to use complementary p and n MOSFET transistors, or if I should only use n MOSFET transistors.

Using complementary transistors has some advantages, but they might also turn into disadvantages. A major disadvantage is each pair of kitty corner transistors now must have opposite highs and lows. Both types must change the voltage from digital 5 Volts to a voltage more suitable to turn the transistor on. Unless the gate voltage must be much higher than the voltage required to drive the desired current through the load, the highest voltage needed would be the power supply voltage.

If we chose to use 4 n MOSFETs, turning each transistor off would be made much simpler, since 0 Volts will do that. Turning the two upper, current source, transistors on would be more difficult, because now the gate voltage must be much higher than the voltage across the load.

This is only the tip of the ice berg. I am sure more challenges lay ahead.

http://www.linkedin.com/in/andrewvall

http://www.elance.com/provprofile?userid=184021&rid=3QOZ

Electrical Design Engineer, Minneapolis, Minnesota

Monday, December 20, 2010

Saturday, December 18, 2010

MOSFET Power Amplifier

In circuit design, power efficiency is a tricky business. The key is to put all of the power originating from the power supply to the load. The trouble is, active circuits do not do that very well over their whole range. Ideally, you want the power dissipated from the transistor to be zero for most of the time. Power is current times voltage. The most efficient amplifier have zero current at maximum voltage, and zero voltage at maximum current. This is the essence of why using a Class D power amplifier or an H bridge is such a good idea. Except, the amplifier is only as good as its components.

The specifications for this design are as follows. It is to have only one power supply, 5 Volts, and a ground. This means that 5 Volts at the gate of the n channel enhancement mode MOSFET should turn the transistor on all the way, and 0 Volts should turn the p channel enhancement mode MOSFET all the way. The MOSFET should have zero volts across from drain to source, when it has been turned on.

The current needed through the amplifier depends on the current through the load. For instance, a speaker usually has an internal resistance of 8 Ohms. Most speakers are rated at a given power level, like 100 Watts.

The current through the load is the square root of the watts divided by the resistance. The current a 100 Watt 8 Ohm speaker is rated for is 3.5 Amps. The resulting voltage across the load is 28 V. Thus, I have misspoken. The voltage level must be boosted to over 28 Volts to drive the load at 3.5 Amps. Thus, the gate voltage for the p channel MOSFET must also be boosted to 28 Volts, or else the voltage from the gate to source will never be equal to zero.

This is the operation of the circuit. Transistor 11 and 12 must never be on at the same time. Same holds true for 21 and 22. The load gets current if 11 and 22 are both on, or 12 and 21 are both on. The current directions for each are opposite of each other. Voltage source 1 and 3 are opposites of each other. Same with Voltage source 2 and 4. They can be driven by the same PWM signal, just so one is high while the other is low.

The next task is to find a way to get 3.5 Amps through the transistors. Since the linear or triode region of operation is the most interest to me, I should start there.

Because I know the current, the gate source voltage, the approximate drain source voltage, and many of the other parameters I want, I can solve for the width to length ratio start designing the other components for the power dissipation. Unfortunately, discrete devices are not so easily designed for. I must pick from an assortment of discrete devices, each with their own advantages. The most important parameter for all of these components is their ability to hold 3.5 Amps of current. Using a site like Digikey streamlines the process of narrowing down a selection, but the task is still daunting. That is the next step in the process.

Microelectronic Circuit Design, Richard Jaeger

http://en.wikipedia.org/wiki/Watt

http://www.linkedin.com/in/andrewvall

http://www.elance.com/provprofile?userid=184021&rid=3QOZ

Electrical Design Engineer, Minneapolis, Minnesota

The specifications for this design are as follows. It is to have only one power supply, 5 Volts, and a ground. This means that 5 Volts at the gate of the n channel enhancement mode MOSFET should turn the transistor on all the way, and 0 Volts should turn the p channel enhancement mode MOSFET all the way. The MOSFET should have zero volts across from drain to source, when it has been turned on.

The current needed through the amplifier depends on the current through the load. For instance, a speaker usually has an internal resistance of 8 Ohms. Most speakers are rated at a given power level, like 100 Watts.

The current through the load is the square root of the watts divided by the resistance. The current a 100 Watt 8 Ohm speaker is rated for is 3.5 Amps. The resulting voltage across the load is 28 V. Thus, I have misspoken. The voltage level must be boosted to over 28 Volts to drive the load at 3.5 Amps. Thus, the gate voltage for the p channel MOSFET must also be boosted to 28 Volts, or else the voltage from the gate to source will never be equal to zero.

This is the operation of the circuit. Transistor 11 and 12 must never be on at the same time. Same holds true for 21 and 22. The load gets current if 11 and 22 are both on, or 12 and 21 are both on. The current directions for each are opposite of each other. Voltage source 1 and 3 are opposites of each other. Same with Voltage source 2 and 4. They can be driven by the same PWM signal, just so one is high while the other is low.

The next task is to find a way to get 3.5 Amps through the transistors. Since the linear or triode region of operation is the most interest to me, I should start there.

For n channel enhancement mode MOSFET

For p channel enhancement mode MOSFET

So, there lies the problem. The smaller the drain source voltage is, the smaller the drain current. The electron mobility and the oxide capacitance are essentially the same for most silicon devices The electron mobility depends on temperature and impurity concentrations. The electron mobility is 40% less for p channel devices. The largest contributing factor is the width to length ratio.Because I know the current, the gate source voltage, the approximate drain source voltage, and many of the other parameters I want, I can solve for the width to length ratio start designing the other components for the power dissipation. Unfortunately, discrete devices are not so easily designed for. I must pick from an assortment of discrete devices, each with their own advantages. The most important parameter for all of these components is their ability to hold 3.5 Amps of current. Using a site like Digikey streamlines the process of narrowing down a selection, but the task is still daunting. That is the next step in the process.

Microelectronic Circuit Design, Richard Jaeger

http://en.wikipedia.org/wiki/Watt

http://www.linkedin.com/in/andrewvall

http://www.elance.com/provprofile?userid=184021&rid=3QOZ

Electrical Design Engineer, Minneapolis, Minnesota

Thursday, December 16, 2010

LED and resistor

There are many different options for controlling an LED. If the current is small, and the power dissipated not very great, a simple resistor would suffice.

A resistance in series with the LED will limit the current through it. One must make sure there is adequate voltage across the LED to it on. A quick look at the data sheet can tell a person a voltage and a current to go along with that voltage, using the voltage current characteristics graph. Then all they have to do is subtract that voltage from the power supply, and find the resistance value that will allow that specified current through for that amount of voltage.

http://www.linkedin.com/in/andrewvall

http://www.elance.com/provprofile?userid=184021&rid=3QOZ

Electrical Design Engineer, Minneapolis, Minnesota

A resistance in series with the LED will limit the current through it. One must make sure there is adequate voltage across the LED to it on. A quick look at the data sheet can tell a person a voltage and a current to go along with that voltage, using the voltage current characteristics graph. Then all they have to do is subtract that voltage from the power supply, and find the resistance value that will allow that specified current through for that amount of voltage.

http://www.linkedin.com/in/andrewvall

http://www.elance.com/provprofile?userid=184021&rid=3QOZ

Electrical Design Engineer, Minneapolis, Minnesota

Saturday, December 4, 2010

Low Pass Filter for an H-Bridge

Analog signals are easily corrupted. Unless the line they are on is relatively short, their fidelity will be compromised, and the signal will be lost. This is most apparent for sound signals to speakers. Professional engineers spend years fine tuning the system, so noise will be kept at a minimum. Amateur systems keep all of the components close together and lines relatively short, so that noise will not be an issue. What if you want to place speakers clear on the other side of a room? No analog solution exists, or is prohibitively expensive.

A digital solution might exist, granted that it is fast enough. Some more information on what that solution might entail exists here. It consists of either a class D amplifier or an H bridge, driven by PWM, and using a carrier signal. To filter out the carrier signal after the class D amplifier requires either an RC, RLC, or active filter. The problem with all of the class D amplifier is it requires the use of two power supplies.

The H bridge doesn't require two power supplies, but the choice of filters is much more limited. Here is one implementation.

It has two inductors, in series with the load (resistor), and a capacitor in parallel with the load. Here is a close up of the filter.

The resistance and capacitance form an impedance, and all the currents are equal.

The currents, being equal, is just the voltage across the filter divided by the impedance.

The voltage of interest is that across the resistance.

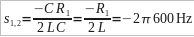

What results is a second order low pass filter, where omega not is the cut off frequency, and Q is the amplitude at that frequency. To obtain a maximally flat response, Q must equal the square root of one over two. The cut off frequency is this.

Q is this.

Leading to this.

Again, as with the other passive filters, to obtain a small cut off frequency, the inductor and capacitor will have to be very large. The carrier signal will have to be as large as possible, to keep the components economical and small. Clearly, this is no small engineering feat.

http://www.linkedin.com/in/andrewvall

http://www.elance.com/provprofile?userid=184021&rid=3QOZ

Electrical Design Engineer, Minneapolis, Minnesota

A digital solution might exist, granted that it is fast enough. Some more information on what that solution might entail exists here. It consists of either a class D amplifier or an H bridge, driven by PWM, and using a carrier signal. To filter out the carrier signal after the class D amplifier requires either an RC, RLC, or active filter. The problem with all of the class D amplifier is it requires the use of two power supplies.

The H bridge doesn't require two power supplies, but the choice of filters is much more limited. Here is one implementation.

It has two inductors, in series with the load (resistor), and a capacitor in parallel with the load. Here is a close up of the filter.

The resistance and capacitance form an impedance, and all the currents are equal.

The currents, being equal, is just the voltage across the filter divided by the impedance.

The voltage of interest is that across the resistance.

What results is a second order low pass filter, where omega not is the cut off frequency, and Q is the amplitude at that frequency. To obtain a maximally flat response, Q must equal the square root of one over two. The cut off frequency is this.

Q is this.

Leading to this.

Again, as with the other passive filters, to obtain a small cut off frequency, the inductor and capacitor will have to be very large. The carrier signal will have to be as large as possible, to keep the components economical and small. Clearly, this is no small engineering feat.

http://www.linkedin.com/in/andrewvall

http://www.elance.com/provprofile?userid=184021&rid=3QOZ

Electrical Design Engineer, Minneapolis, Minnesota

Thursday, November 25, 2010

FFT and LED generator in PIC

I have been doing a lot of thinking, and thanks to this blog, it has been out loud.

The PIC Microcontroller needs an interface to talk to a computer. Using USB has some perks, namely being very convenient, but it requires a lot of overhead. Based on my experience, you need special drivers for the computer, a lot of extra special code on the microcontroller, and it isn't all that reliable anyway. There might be some special configuration that works the best, but it would require some leg work. Trouble is, that leg work could be for nothing, if it keeps changing, and is drastically different for each device. I would like something that is more stable and universal, with out a lot of extra over head.

RS-232 just might be that answer. Most computers already have that capability built in, and I do not need a device driver just to have the computer talk to the PIC. The code size on the PIC is much smaller, and while the way you program a microcontroller might be different for each, they are much more transparent in how it is done.

I have some more research material below. Time to read up!

Open Directory on the PIC

Wikipedia on the PIC has information on hardware and software to program the PIC.

PIC18F4455 data sheet indispensable in information.

ICSP programmers for PIC

Wikipedia on LED has information on types and powering LED.

Wikipedia on LED Power Sources powering LED.

http://www.linkedin.com/in/andrewvall

http://www.elance.com/provprofile?userid=184021&rid=3QOZ

Electrical Engineer, Minneapolis, Minnesota

The PIC Microcontroller needs an interface to talk to a computer. Using USB has some perks, namely being very convenient, but it requires a lot of overhead. Based on my experience, you need special drivers for the computer, a lot of extra special code on the microcontroller, and it isn't all that reliable anyway. There might be some special configuration that works the best, but it would require some leg work. Trouble is, that leg work could be for nothing, if it keeps changing, and is drastically different for each device. I would like something that is more stable and universal, with out a lot of extra over head.

RS-232 just might be that answer. Most computers already have that capability built in, and I do not need a device driver just to have the computer talk to the PIC. The code size on the PIC is much smaller, and while the way you program a microcontroller might be different for each, they are much more transparent in how it is done.

I have some more research material below. Time to read up!

Open Directory on the PIC

Wikipedia on the PIC has information on hardware and software to program the PIC.

PIC18F4455 data sheet indispensable in information.

ICSP programmers for PIC

Wikipedia on LED has information on types and powering LED.

Wikipedia on LED Power Sources powering LED.

http://www.linkedin.com/in/andrewvall

http://www.elance.com/provprofile?userid=184021&rid=3QOZ

Electrical Engineer, Minneapolis, Minnesota

Monday, November 22, 2010

Low Pass Filter

After some deliberation, I have decided to not use an RLC circuit, and to go with an active, two pole, low pass filter.

I think it would be simplest to use Nodal Analysis, with two unknowns, and two equations. The use of conductances can make nodal analysis much easier, so I think I will use that. The conductance is simply the reciprocal of the resistance.

The first nodal equation:

The second nodal equation:

Solving the second nodal equation for V1:

Substituting this into the first nodal equation:

Simplifying

Solving for V2, which is the output:

Combining like terms:

Where omega is the cut off frequency, and Q is the gain of the amplifier at omega. For the best possible filter performance, while remaining maximally flat, Q should be between 0.707 and 1. I do not want the gain to roll off too quickly, nor do I want too high of a peak at the cut off frequency.

R1 and R2 should be on the same order as the output resistance of the microphone, C1 could equal C2. If that is the case, the equations simplify.

Unfortunately, this configuration can only produce a Q of 0.5, and only with equal resistances. To simplify the number of components needed, both resistances will be equal.

C1 must be between two and four times C2 to achieve a high enough Q. The resistance is 1000 Ohms.

With C1 two time C2, and R equal to 1000 Ohms

C2 is 100 nF, C1 is 200 nF.

Looking at the simulation, in log log scale, I see that it does not roll off at a low enough frequency. I choose C2 to be 200 nF, and C1 to be 400 nF. Now the drop off starts at 200 Hz, instead of at around 700 Hz.

In conclusion, this is the operation of the active, two pole, low pass filter. Unlike the RLC, higher resistance smaller capacitances can achieve smaller cut off frequencies. Care must be taken to make sure operational amplifier non-linearities are properly accounted for, but this is a valid way of implementing a low pass amplifier.

http://www.linkedin.com/in/andrewvall

http://www.elance.com/provprofile?userid=184021&rid=3QOZ

Electrical Engineer, Minneapolis, Minnesota

I think it would be simplest to use Nodal Analysis, with two unknowns, and two equations. The use of conductances can make nodal analysis much easier, so I think I will use that. The conductance is simply the reciprocal of the resistance.

The first nodal equation:

The second nodal equation:

Solving the second nodal equation for V1:

Substituting this into the first nodal equation:

Simplifying

Solving for V2, which is the output:

Combining like terms:

Where omega is the cut off frequency, and Q is the gain of the amplifier at omega. For the best possible filter performance, while remaining maximally flat, Q should be between 0.707 and 1. I do not want the gain to roll off too quickly, nor do I want too high of a peak at the cut off frequency.

R1 and R2 should be on the same order as the output resistance of the microphone, C1 could equal C2. If that is the case, the equations simplify.

Unfortunately, this configuration can only produce a Q of 0.5, and only with equal resistances. To simplify the number of components needed, both resistances will be equal.

C1 must be between two and four times C2 to achieve a high enough Q. The resistance is 1000 Ohms.

With C1 two time C2, and R equal to 1000 Ohms

C2 is 100 nF, C1 is 200 nF.

Looking at the simulation, in log log scale, I see that it does not roll off at a low enough frequency. I choose C2 to be 200 nF, and C1 to be 400 nF. Now the drop off starts at 200 Hz, instead of at around 700 Hz.

In conclusion, this is the operation of the active, two pole, low pass filter. Unlike the RLC, higher resistance smaller capacitances can achieve smaller cut off frequencies. Care must be taken to make sure operational amplifier non-linearities are properly accounted for, but this is a valid way of implementing a low pass amplifier.

http://www.linkedin.com/in/andrewvall

http://www.elance.com/provprofile?userid=184021&rid=3QOZ

Electrical Engineer, Minneapolis, Minnesota

Wednesday, November 17, 2010

RLC

I am trying to find a simple RLC filter, with few components. The component values should be readily available and not too large.

Their are two flavors of the RLC low pass filters. One is where the resistance is in series with the inductor, the other is where the resistance is in parallel with the capacitance. What happens when these two flavors are combined?

The equivalent resistance between R2 and C1 is as follows.

The output is just a voltage divider.

What can I see intuitively from this equation? Well, when s or j omega equals zero, the output is simply the input times a voltage divider. Omega squared is simply the capacitance times the inductance.

Can the equation be simplified? The inductance should be very small, so the middle term should simplify.

I would like the filter to be critically damped. When does that happen?

When the radical equals zero, it is considered to be critically damped, where the system returns to equilibrium as soon as possible, with no ringing or oscillations.

If R2 is much greater than R1, then the radical can be further simplified.

The radical must to equals zero.

If the capacitance equals the reciprocal of R1, then the roots are simply this.

But this creates a problem. R1 should be very small. This means that C would need to be relatively large, which we don't want. Thus, I will keep the root as it was.

Because R1 equals 1 kilo Ohm, L equals 0.1 Henry. Even if R1 equals 1 Ohm, the inductance would still be 0.1 mH.

I have come to the conclusion that RLC low pass filtering circuits are best used for attenuating very high frequencies.

It seems my best option is to use an active low pass filtering circuit. This way, the output resistance of the microphone will not effect the filtering equations, I can use much smaller values, and I can make the filter PCB foot print relatively small, even if the part number is relatively large.

http://www.linkedin.com/in/andrewvall

http://www.elance.com/provprofile?userid=184021&rid=3QOZ

Electrical Engineer, Minneapolis, Minnesota

Their are two flavors of the RLC low pass filters. One is where the resistance is in series with the inductor, the other is where the resistance is in parallel with the capacitance. What happens when these two flavors are combined?

The equivalent resistance between R2 and C1 is as follows.

The output is just a voltage divider.

What can I see intuitively from this equation? Well, when s or j omega equals zero, the output is simply the input times a voltage divider. Omega squared is simply the capacitance times the inductance.

Can the equation be simplified? The inductance should be very small, so the middle term should simplify.

I would like the filter to be critically damped. When does that happen?

When the radical equals zero, it is considered to be critically damped, where the system returns to equilibrium as soon as possible, with no ringing or oscillations.

If R2 is much greater than R1, then the radical can be further simplified.

The radical must to equals zero.

If the capacitance equals the reciprocal of R1, then the roots are simply this.

But this creates a problem. R1 should be very small. This means that C would need to be relatively large, which we don't want. Thus, I will keep the root as it was.

Because R1 equals 1 kilo Ohm, L equals 0.1 Henry. Even if R1 equals 1 Ohm, the inductance would still be 0.1 mH.

I have come to the conclusion that RLC low pass filtering circuits are best used for attenuating very high frequencies.

It seems my best option is to use an active low pass filtering circuit. This way, the output resistance of the microphone will not effect the filtering equations, I can use much smaller values, and I can make the filter PCB foot print relatively small, even if the part number is relatively large.

http://www.linkedin.com/in/andrewvall

http://www.elance.com/provprofile?userid=184021&rid=3QOZ

Electrical Engineer, Minneapolis, Minnesota

Monday, November 15, 2010

The Filter

The frequencies of interest are under 600 Hz. I need to put a filter just after the microphone to attenuate the unwanted frequencies. I would like this filter to take up as little PCB real estate as possible, make it very small and simple.

I would like a second order low pass filter. A passive RC network is the simplest, but is first order. A second order RC network contains at least four components, and also attenuates the passband.

An active filter has a second order implementation, but is much more complex. I would need to supply power to the active devices, the foot print would be much larger, and there would be more parts to fail. I would rather not use any of these implementations.

The simplest second order filter possible is likely an RLC filter. To make a low pass, second order configuration, the inductor is in series with the signal, the capacitor is in parallel with the signal. The inductor is a short to small frequencies and is an open to large frequencies. The capacitor is an open to small frequencies, and a short to large frequencies.

The input is a 1 kilo Ohm resistance microphone, CMB-6544PF. The output is an infinite impedance amplifier.

This is the circuit. The one kOhm resistor is part of the signal source. This creates a difficulty.

Converting L and C to their equivalent S domain impedances.

Equating terms.

and

So, accordingly.

There lies the problem. Because the output impedance of the microphone is so large, the resulting inductance is very large. To have an inductance that has an economical value, the resistance would need to be very small. An inductance of this size is likely to be very large, and have a lot more problems associated with it.

After some thought, a first order RC filter seems the best option.

A QUCS simulation confirms that while both components are more physically realizable, the point where the attenuation reaches 10 % is at 5 kHz.

http://www.linkedin.com/in/andrewvall

http://www.elance.com/provprofile?userid=184021&rid=3QOZ

Electrical Engineer, Minneapolis, Minnesota

I would like a second order low pass filter. A passive RC network is the simplest, but is first order. A second order RC network contains at least four components, and also attenuates the passband.

An active filter has a second order implementation, but is much more complex. I would need to supply power to the active devices, the foot print would be much larger, and there would be more parts to fail. I would rather not use any of these implementations.

The simplest second order filter possible is likely an RLC filter. To make a low pass, second order configuration, the inductor is in series with the signal, the capacitor is in parallel with the signal. The inductor is a short to small frequencies and is an open to large frequencies. The capacitor is an open to small frequencies, and a short to large frequencies.

The input is a 1 kilo Ohm resistance microphone, CMB-6544PF. The output is an infinite impedance amplifier.

This is the circuit. The one kOhm resistor is part of the signal source. This creates a difficulty.

Converting L and C to their equivalent S domain impedances.

Equating terms.

and

So, accordingly.

There lies the problem. Because the output impedance of the microphone is so large, the resulting inductance is very large. To have an inductance that has an economical value, the resistance would need to be very small. An inductance of this size is likely to be very large, and have a lot more problems associated with it.

After some thought, a first order RC filter seems the best option.

A QUCS simulation confirms that while both components are more physically realizable, the point where the attenuation reaches 10 % is at 5 kHz.

http://www.linkedin.com/in/andrewvall

http://www.elance.com/provprofile?userid=184021&rid=3QOZ

Electrical Engineer, Minneapolis, Minnesota

Thursday, November 4, 2010

How to put FFT in a microcontroller? 2

What do I need from a Microcontroller?

As my Windows 7 laptop has been acting up lately, I will be using Linux. While everything might not be as neatly packaged as might happen on Windows, Linux should have all the necessary packages I need. Currently I run Fedora 12. My development environment is Eclipse. There is a collection of tools for the Micrchip PIC called gputils, gpsim, and ktechlab. Both gputils and gpsim are run from the command line. Ktechlab includes gpsim functionality. Piklab is an IDE that uses gputils and gpsim. The only problem is all of these programs are in alpha and beta. I have been rather impressed with linux software to date, so I will give them a try.

http://gputils.sourceforge.net/

http://gpsim.sourceforge.net/

http://www.eclipse.org/

http://www.microchip.com/

A way of serially programming the PIC is using picprog. They also describe the hardware necessary to connect the two. This is also run from the command line.

http://hyvatti.iki.fi/~jaakko/pic/picprog.html

I decided to use the 16 Bit Core size, which knocks Digikey down to 25 pages from more than 100. I am choosing Microchip, a PIC core processor, 40 MIPs speed. There is still so much to choose from.

http://www.linkedin.com/in/andrewvall

http://www.elance.com/provprofile?userid=184021&rid=3QOZ

Electrical Design Engineer in Minneapolis Minnesota

As my Windows 7 laptop has been acting up lately, I will be using Linux. While everything might not be as neatly packaged as might happen on Windows, Linux should have all the necessary packages I need. Currently I run Fedora 12. My development environment is Eclipse. There is a collection of tools for the Micrchip PIC called gputils, gpsim, and ktechlab. Both gputils and gpsim are run from the command line. Ktechlab includes gpsim functionality. Piklab is an IDE that uses gputils and gpsim. The only problem is all of these programs are in alpha and beta. I have been rather impressed with linux software to date, so I will give them a try.

http://gputils.sourceforge.net/

http://gpsim.sourceforge.net/

http://www.eclipse.org/

http://www.microchip.com/

A way of serially programming the PIC is using picprog. They also describe the hardware necessary to connect the two. This is also run from the command line.

http://hyvatti.iki.fi/~jaakko/pic/picprog.html

I decided to use the 16 Bit Core size, which knocks Digikey down to 25 pages from more than 100. I am choosing Microchip, a PIC core processor, 40 MIPs speed. There is still so much to choose from.

http://www.linkedin.com/in/andrewvall

http://www.elance.com/provprofile?userid=184021&rid=3QOZ

Electrical Design Engineer in Minneapolis Minnesota

Wednesday, November 3, 2010

How to put FFT in a microcontroller? 1

I would like to make an LED display that will flash to the beat of various music.

Here are some requirements.

I could either go digital or analog, depending what I want from the system. If there was only one range of frequencies I was interested in, with only one set of LEDs, analog would work the best, because it would be the simplest: only one filter, LED driver, and the LEDs. Because I am interested in several groups of LEDs, all controlled by a different range of frequencies, the analog solution is out. With a digital system, like with a microcontroller, I could easily program in different frequencies using a digital filter, or use an FFT algorithm, to target any set of frequencies I want. The problem with using a digital filter is that it is for only one range of frequencies. I would like each group of LEDs to be controlled by different sets of frequencies. It looks like my best option is to use an FFT algorithm, because that divides a frequency range (half Nyquest frequency divided into N samples), and quantifies that with an amplitude.

I would like to choose a Microcontroller that is fairly easy to operate, yet has enough functionality to get the job done. I have looked into the Texas Instruments Piccolo, but I have yet to see anything that would make me want to pursue it any further. It lacks a user base, all of the material comes from TI. Its documents and coding are confusing. The site says they wanted to create a microcontroller that was sufficiently easy to use, so that developers could easily apply it to their projects, but have they really done that? They have a lot of existing projects, but I don't quite see how to change those projects to fit my needs. I think I am better off going with a different microcontroller, which is what I will be researching next.

http://www.linkedin.com/in/andrewvall

http://www.elance.com/provprofile?userid=184021&rid=3QOZ

Electrical Design Engineer, Minneapolis, Minnesota

Here are some requirements.

- Their will be multiple LED groups that will have different controllers for each.

- Each group will be controlled by a different range of frequencies.

- The system must be capable of frequencies past 40 kHz.

- The whole system should not waste power.

- LED should draw little current.

I could either go digital or analog, depending what I want from the system. If there was only one range of frequencies I was interested in, with only one set of LEDs, analog would work the best, because it would be the simplest: only one filter, LED driver, and the LEDs. Because I am interested in several groups of LEDs, all controlled by a different range of frequencies, the analog solution is out. With a digital system, like with a microcontroller, I could easily program in different frequencies using a digital filter, or use an FFT algorithm, to target any set of frequencies I want. The problem with using a digital filter is that it is for only one range of frequencies. I would like each group of LEDs to be controlled by different sets of frequencies. It looks like my best option is to use an FFT algorithm, because that divides a frequency range (half Nyquest frequency divided into N samples), and quantifies that with an amplitude.

I would like to choose a Microcontroller that is fairly easy to operate, yet has enough functionality to get the job done. I have looked into the Texas Instruments Piccolo, but I have yet to see anything that would make me want to pursue it any further. It lacks a user base, all of the material comes from TI. Its documents and coding are confusing. The site says they wanted to create a microcontroller that was sufficiently easy to use, so that developers could easily apply it to their projects, but have they really done that? They have a lot of existing projects, but I don't quite see how to change those projects to fit my needs. I think I am better off going with a different microcontroller, which is what I will be researching next.

http://www.linkedin.com/in/andrewvall

http://www.elance.com/provprofile?userid=184021&rid=3QOZ

Electrical Design Engineer, Minneapolis, Minnesota

Subscribe to:

Comments (Atom)